1.

Contact Reiloy USA.

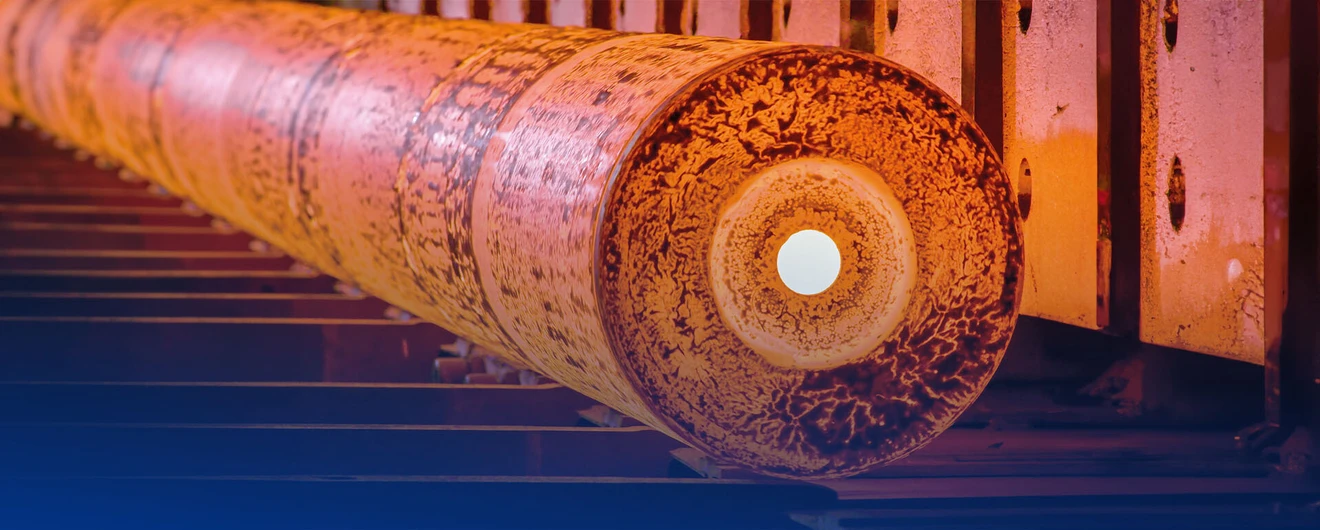

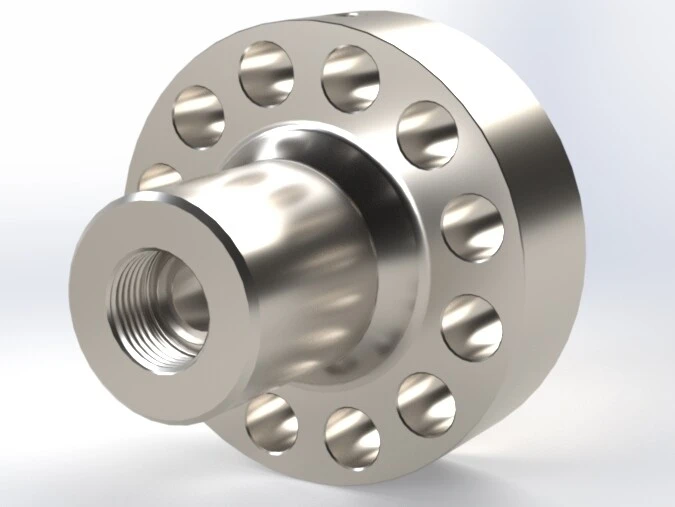

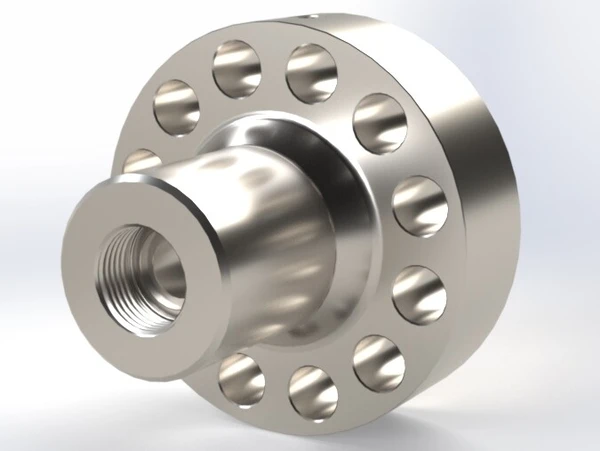

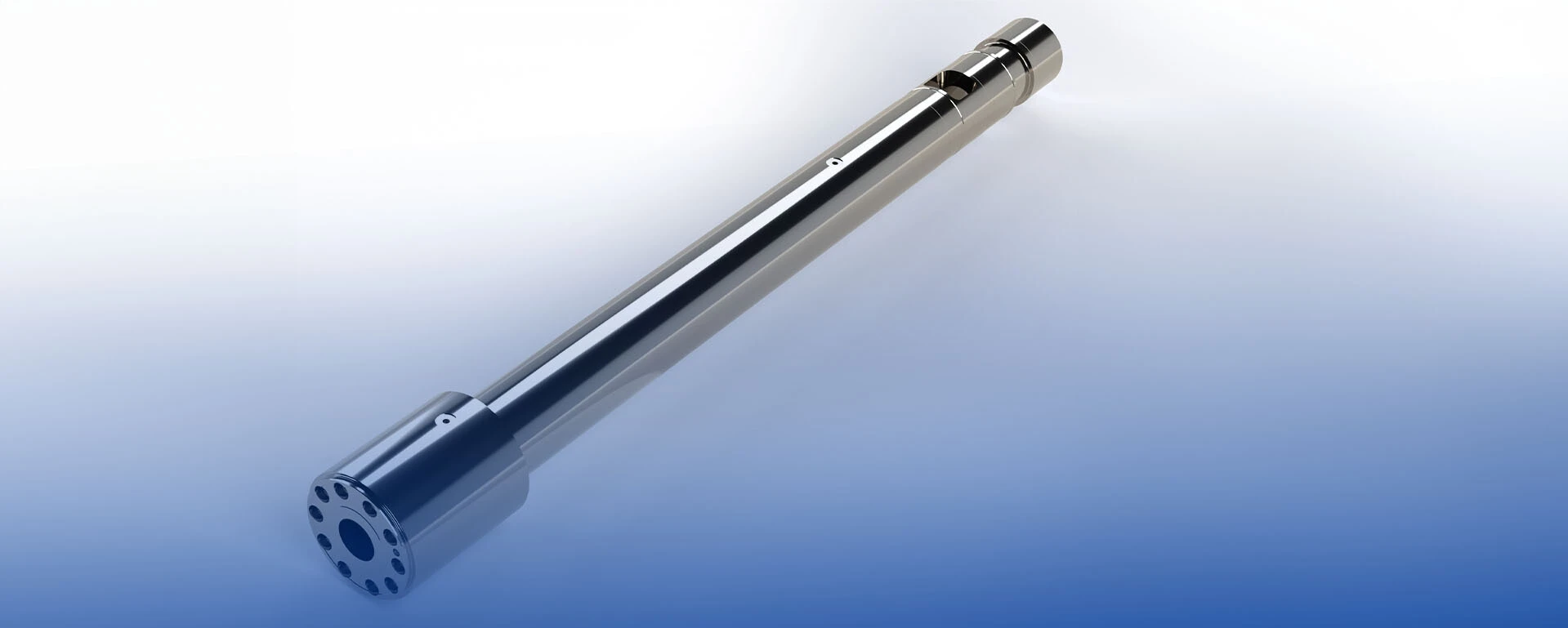

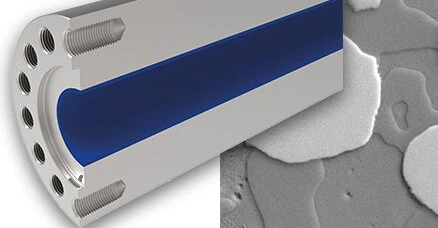

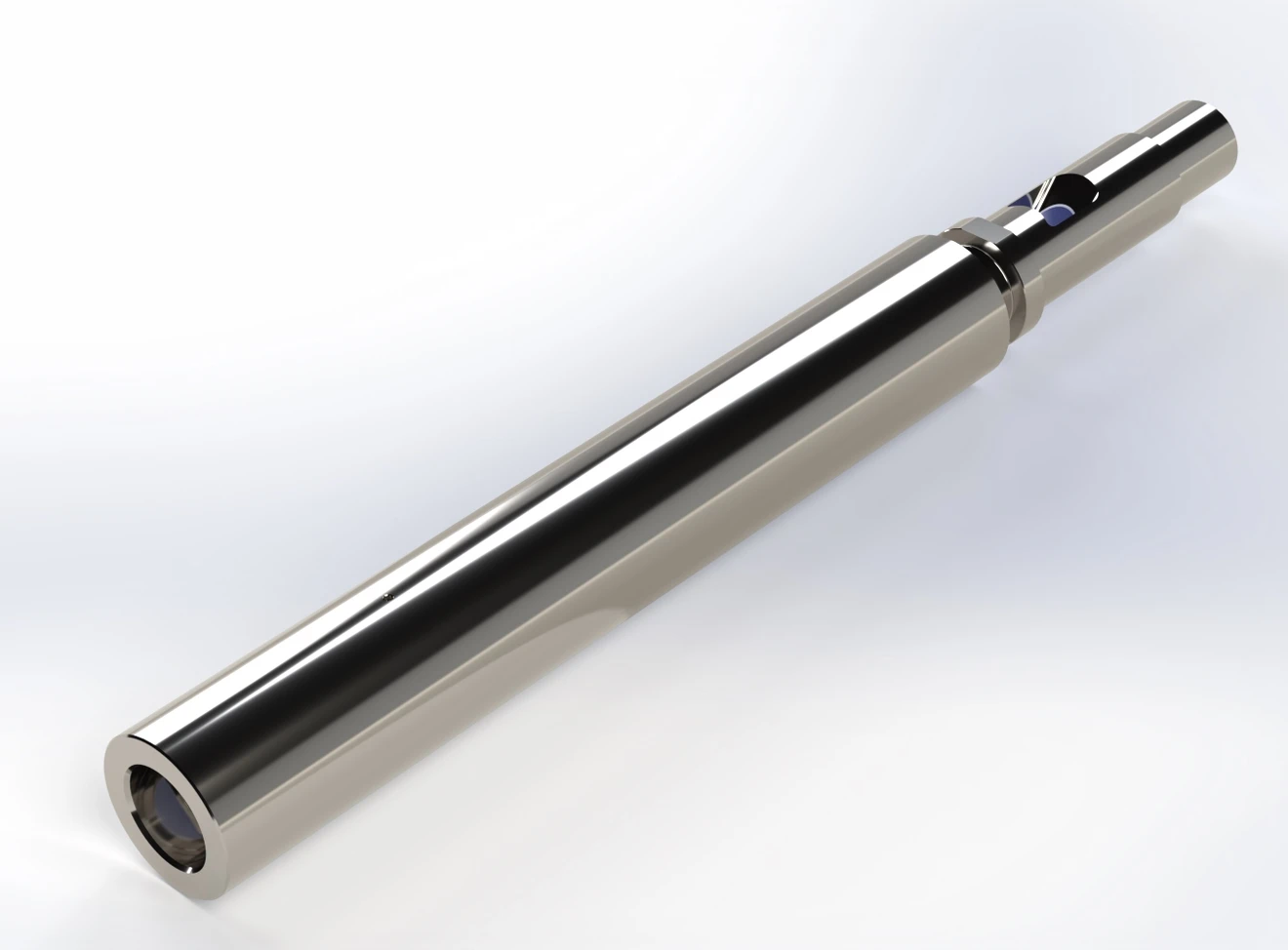

Barrels for Extrusion and Injection Molding

Barrels of consistent quality that provide longer protection for your plasticizing units against adhesion, abrasion, and corrosion, even for processing raw materials that cause intensive wear and tear.

HIGH QUALITY WITH TOP-CLASS WEAR PROTECTION

High Productivity That Is Cost-Effective When Using High Performance Barrels

Reiloy USA offers you bimetallic barrels with wear protection that match your production requirements exactly and allow you to continue production for a longer period of time. At Reiloy you'll find the only bimetallic barrels in the world, made by a single source from raw material to finished product, with in-house powder production, ensuring consistent quality from start to finish.

OUR EXPERTISE

Why choose barrels from Reiloy USA

WHAT WOULD YOU LIKE TO PRODUCE?

Choose Your Reiloy Bimetallic Barrel

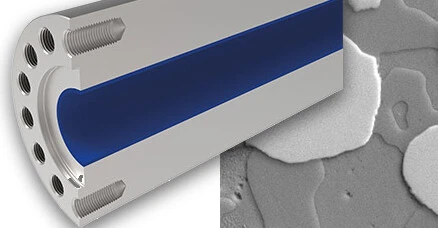

For plastics with a filler content up to 30%

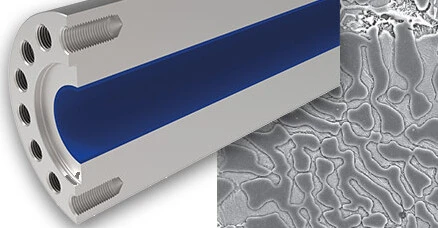

Iron based alloy with primarily solidified chrome carbides, great wear package at an economical price.

ABS, ASA, CA, COC, EVA, HDPE, HIPS, LDPE, PA, PBT, PC, PEEK, PEI, PESU, PET, PF, PMMA, POM, PP, PPA, PPS, PPSU, PS, PS transparent, PSU, PVC-C, PVC-P, PVC-U, PVDF, SAN, SB, TPE, TPU

Injection Reiloy Standard R121

Extrusion Reiloy Standard R121

| Wear resistance | +++ | |

| Corrosion resistance | +++ | |

| Layer thickness | 1.5 mm | |

| Roughness Ra | min. 0.2 – max. 0.8 | |

| Inner diameter | 14 – 400 mm | |

| Outside diameter | max. 600 mm | |

| Length | max. 9,000 mm | |

| Hardness at room temperature | min. 65 HRC | |

| Main alloy component | Cr, Ni, Mo, B | |

| Structural description | Martensitic iron-based alloy with primarily solidified chrome carbides and Carbo-Boride Phases |

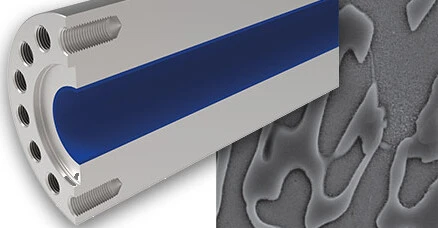

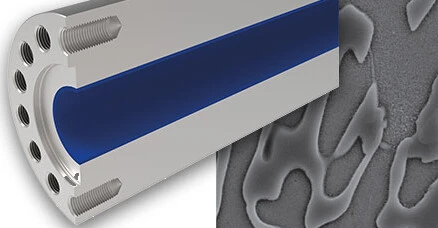

For plastics with a filler content greater than 30%

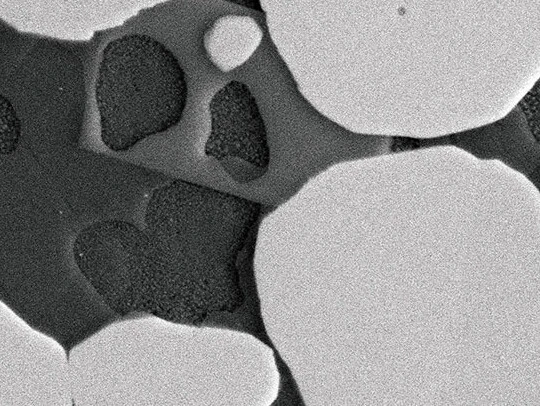

Nickel Matrix Alloy with Tungsten Carbides with an exceptional corrosion and superior wear resistance.

ABS, ASA, EVA, HDPE, HIPS, LDPE, PA, PBT, PEEK, PEI, PESU, PET, POM, PP, PPA, PPS, PPSU, PSU, PVC-C, PVC-P, PVC-U, TPE, TPU

Injection Reiloy Standard R241

Extrusion Reiloy Standard R241

| Wear resistance | +++++ | |

| Corrosion Resistance | +++++ | |

| Layer thickness | min. 1.0 mm | |

| Roughness Ra | min. 0.3 – max. 0.8 | |

| Inner diameter | 15 – 300 mm | |

| Outside diameter | max. 600 mm | |

| Length | max. 9,000 mm | |

| Hardness at room temperature | min. 59 HRC | |

| Main alloy component | W, Cr, B | |

| Structural description | Dispersive hardening of a highly corrosive resistant Ni-matrix alloy with thermally stable tungsten carbides |

Nickel-Cobalt Alloy with Chromium Carbides results in exceptional corrosion resistant package.

ABS, ASA, CA, COC, EVA, HDPE, HIPS, LDPE, PA, PBT, PC, PEEK, PEI, PESU, PET, PF, PMMA, POM, PP, PPA, PPS, PPSU, PS, PS transparent, PSU, PVC-C, PVC-P, PVC-U, PVDF, SAN, SB, TPE, TPU

Injection Reiloy Standard R115

Extrusion Reiloy Standard R115

| Wear resistance | + | |

| Corrosion Resistance | +++++ | |

| Layer thickness | min. 1.5 mm | |

| Roughness Ra | min. 0.2 – max. 0.8 | |

| Inner diameter | 15 – 105 mm | |

| Outside diameter | max. 350 mm | |

| Length | max. 3,000 mm | |

| Hardness at room temperature | min. 55 HRC, Di > 60 mm min. 47 HRC | |

| Main alloy component | Co, Cr, B | |

| Structural description | Nickel-cobalt base alloy with fine precipitation of primary solidified nickel borides and eutectically solidified chromium carbides |

Nickel Matrix alloy with common tungsten carbides providing both a wear as well as high corrosion.

ABS, ASA, EVA, HDPE, HIPS, LDPE, PA, PBT, PEEK, PEI, PESU, PET, POM, PP, PPA, PPS, PPSU, PSU, PVC-R, PVC-F, PVC-C, PFA, TPE, TPU

Injection Reiloy Standard R239

Extrusion Reiloy Standard R239

| Wear resistance | ++++ | |

| Corrosion Resistance | +++++ | |

| Layer thickness | min. 1.0 mm | |

| Roughness Ra | min. 0.2 – max. 0.8 | |

| Inner diameter | 18 – 165 mm | |

| Outside diameter | max. 290 mm | |

| Length | max. 3,000 mm | |

| Hardness at room temperature | min. 58 HRC | |

| Main alloy component | W, Cr, B | |

| Structural description | Dispersive hardening of a highly corrosive resistant Ni-matrix alloy with common tungsten carbides |

KEY DATA AT A GLANCE

Barrels up to 6 Meters Long

| CASTING: Maize, KS | |

| Inside Diameter | 18-90 mm (appr.) |

| Outside Diameter | Up to 230 mm |

| Length | Up to 2400 mm |

| MACHINING: Maize, KS | |

| Max. Diameter | 430 mm |

| Max. Weight | 4 tons |

| Max. Length | 6000 mm |

NEED ADDITIONAL JUSTIFICATION?

Reiloy Barrels Are:

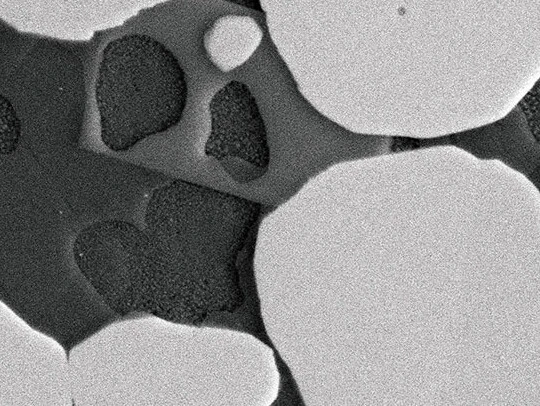

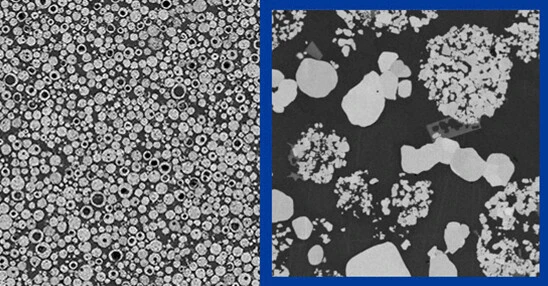

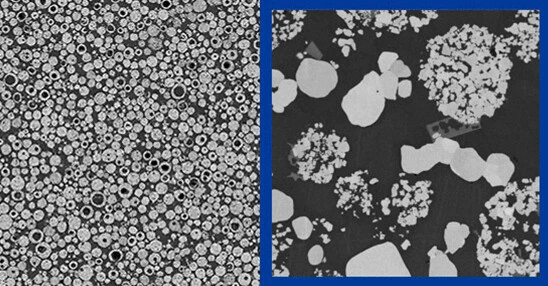

THE WORLD'S ONLY BARRELS FROM A SINGLE SOURCE

Outstanding Wear Protection and Consistent Quality From Powder to End Product

Reiloy Barrels are the world's only barrels made from a single source. We are the only barrel manufacturer that produces our own alloy powders to ensure consistent barrel quality and lasting wear protection that maximizes your productivity and quality.

HOW TO BENEFIT FROM REILOY USA BARRELS

Master Production Challenges with Ease

SOMETHING TO LOOK FORWARD TO

Highlights of Your Reiloy USA Barrels