1.

Arrange a consultation.

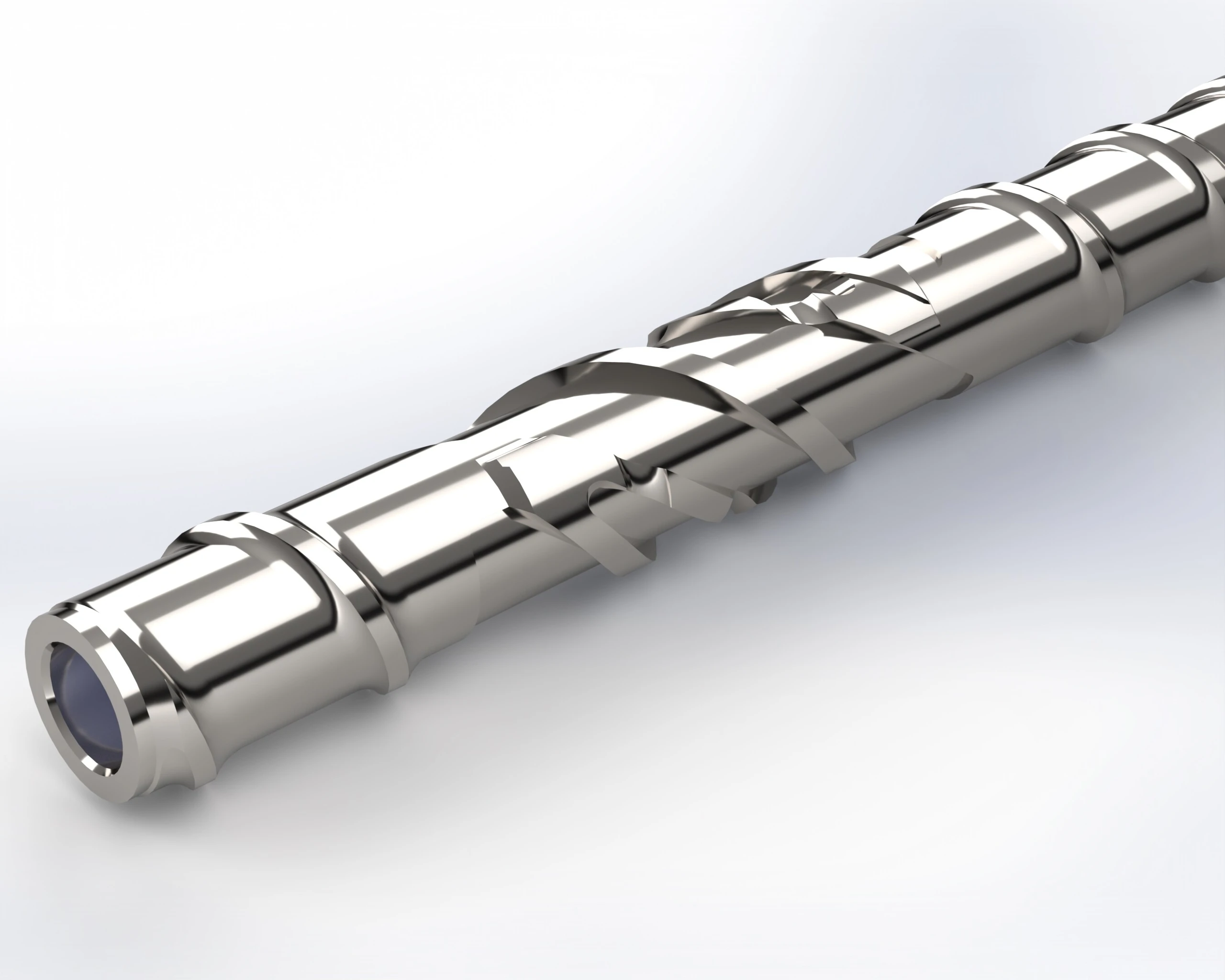

Injection Molding Screws and Extrusion Screws

Operate your plasticizing units with screws that suit your application and withstand even the most wear-intensive materials for longevity, so you can master your production challenges with ease.

YOUR PROJECT - OUR PRECISION

Your Screws Should Match Your Goals

Did you know that processing problems during extrusion or injection molding can be caused by a screw that is not optimally matched to the application? Screw variations are designed to achieve a special processing result. So, choosing the right screw can already improve your production rate and reduce your part reject rates. There are many mixing screw designs offered that can provide both dispersive, distributive or a combination of both, that result in the reorientation of the resin after it has been melted. Together we will find the perfect individual solution for you so you can reach your production goals.

What would you like to produce?

Choose Your Screw

Screw <50mm: PM9V, 420V (S90V), Elmax, Hastelloy

Screw >/=50mm: PM9V*, 420V (S90V)*, Elmax, Hastelloy, Nitralloy 135, 4140HT, 4340HT

Flight Hardening Options: Nickel-based: Colmonoy 56, 57 and 83

Application Driven Options: Chrome, Ceramic Chrome, Nitride, Carbide Encapsulation

Additional base materials and flight hardening available based on application

Resin will drive screw base material:

ABS, ASA, CA COC, EVA, HDPE, HIPS, LDPE, PA, PBT, PC, PEEK, PEI, PESU, PET, PF, PMMA, POM, PP, PPA, PPS, PPSU, PS, PSU, PVC-C, PVC-R, PVC-F, PVDF, SAN, TPE, TPU

*CPM9V and 420V (S90V) use can be limited by size

Screw <50mm: PM9V, 420V (S90V), Elmax, Hastelloy

Screw >/=50mm: PM9V*, 420V (S90V)*, Elmax, Hastelloy, Nitralloy 135, 4140HT, 4340HT

Flight Hardening Options: Nickel-based: Colmonoy 56, 57 and 83

Application Driven Options: Chrome, Ceramic Chrome, Nitride, Carbide Encapsulation

Additional base materials and flight hardening available based on application

Resin will drive screw base material:

ABS, ASA, CA COC, EVA, HDPE, HIPS, LDPE, PA, PBT, PC, PEEK, PEI, PESU, PET, PF, PMMA, POM, PP, PPA, PPS, PPSU, PS, PSU, PVC-C, PVC-R, PVC-F, PVDF, SAN, TPE, TPU

*CPM9V and 420V (S90V) use can be limited by size

Screw 30-49mm: PM9V or 420V (S90V)

Screw >/=50mm: PM9V*, 420V (S90V)*, Elmax, Hastelloy, Nitralloy 135, 4140HT, 4340HT

Flight Hardening Options: Nickel-based: Colmonoy 56, 57 and 83

Application Driven Options: Chrome, Ceramic Chrome, Nitride, Carbide Encapsulation

Additional base materials and flight hardening available based on application

HDPE, LDPE, PA, PET, PP,

*CPM9V and 420V (S90V) use can be limited by size

Screw 30-49mm: PM9V or 420V (S90V)

Screw >/=50mm: PM9V*, 420V (S90V)*, Elmax, Hastelloy, Nitralloy 135, 4140HT, 4340HT

Flight Hardening Options: Nickel-based: Colmonoy 56, 57 and 83

Application Driven Options: Chrome, Ceramic Chrome, Nitride, Carbide Encapsulation

Additional base materials and flight hardening available based on application

HDPE, LDPE, PA, PET, PP,

*CPM9V and 420V (S90V) use can be limited by size

REILOY USA EAGLE® MIXING

The Unique Reiloy USA Eagle® Design Concept

Our Eagle® and Eagle® Barrier screws continue to set a very high-performance standard by supplying a predictable, repeatable performance that can be counted on day in and day out. In addition to the High-Performance Eagle and Eagle Barrier Mixing screws, we also offer a wide range of mixing screw and mixing element options for both the injection and extrusion industries.

Originally Developed in 1993

Our patent mixer features endless levels of adjustability

Versatile Configuration

Variable adjustments allow the screw to function as either a low-shear or high-shear mixer

Broad Material Compatibility

The design is suitable for processing diverse resins, from ABS to nylon

Enhanced Processing Applications

Applicable to injection molding, extrusion, and more, the mixer improves mixing quality without excessive shear, boosting profitability

Something to look forward to

Highlights of Your Reiloy USA Screws

IMPROVE THE COST-EFFECTIVENESS OF YOUR PLASTICIZING UNIT

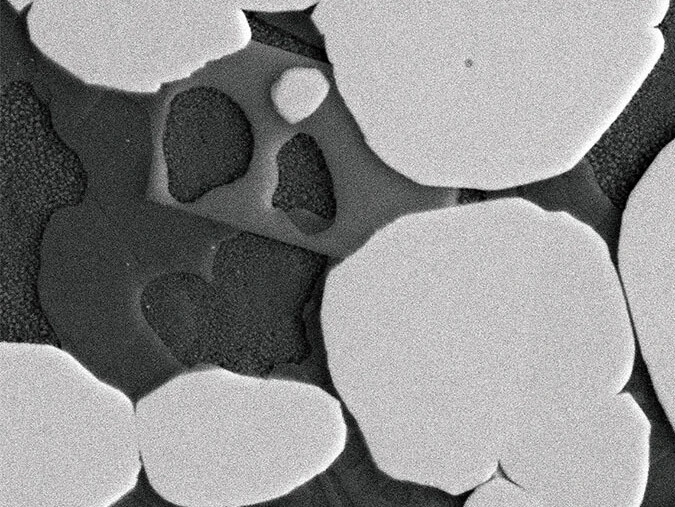

High quality with top-class wear protection

Reiloy USA manufactures screws in a variety of steels. Surface treatments such as gas or ion nitride, or hard chrome plate can be added for additional surface protection. With our expertise and experience, we design screws specifically to increase the efficiency of your production processes and applications.

Securing product quality and process stability sustainably.

Top-class Wear Protection

Reiloy USA manufactures screws in a variety of steels. We can add surface treatments such as gas or ion nitride, or hard chrome plate for additional surface protection. With our expertise and experience, we design screws specifically to increase the efficiency of your production processes and applications.

Material Designation

We choose between heat-treated and hardened condition tool steel, alloy steel, 4340 series or special alloys such as Hastelloy C-276, etc.

Secondary treatment to provide wear resistance

Some materials are either chrome-plated, nitrided or heat-treated.

Flight hard-surfacing

Screws that are not manufactured from solid or stainless tool steels need a flight hard-surfacing material such as: Stellite 6 or 12, Colmonoy 56,57, or 83, etc.

MASTERING PRODUCTION CHALLENGES WITH EASE