Valves and End Caps

Choose locally manufactured front-end components that perfectly fit your needs.

VALVES & END CAPS

The perfect addition

Being the key components to any injection molding setup, valves and end caps are manufactured from steels or alloys that are best suited to the processing environment in which they will be used. Various tool steels that are heat-treated and/or nitrided nickel alloys, chrome plating and special coatings are all options from which to choose.

The sales and engineering team at Reiloy will work with you to determine the best front-end component to fit your needs. Just like Reiloy USA screws and barrels, quality is key. These components are produced in the USA.

TYPES OF VALVES

The Perfect Valves for Your Injection Molding Setup

Non-return valves allow melted resin to flow in front of the screw during plasticating and block the melt from flowing back to the screw during injection. Choose the type that best fit your need.

Free Flow Valve

They can be used when processing most resins and can be custom designed for special applications.

Locking Valve

Locking valves are designed to lock in a specific position and are commonly standard in many AP or EU manufactured machines.

Ball Check Valve

There are several different types of ball check designs, though the most common are side or front discharge assemblies.

Not sure which type of valves you need?

What are you looking for?

Our portfolio

Valves

The function of the non-return valve is to allow melted resin to flow in front of the screw during plasticating and block the melt from flowing back to the screw during injection.

Standard Option:

comprised of H13/D2 combination

Premium Option:

comprised of PM10V/9V combination

Application Driven Options:

420V, Rex76, M4, 20CV, Elmax, Nitride, and Carbide

Standard Option:

comprised of H13/D2 combination

Premium Option:

comprised of PM10V/9V combination

Application Driven Options:

420V, Rex76, M4, 20CV, Elmax, Nitride, and Carbide

Front and Side Discharge Options

Standard Version:

D2 Body - Stainless Steel Ball

Premium Version:

PM10V Body - Stainless Steel Ball

Application Driven Options:

Discussed on a case-by-case basis on Ball Checks

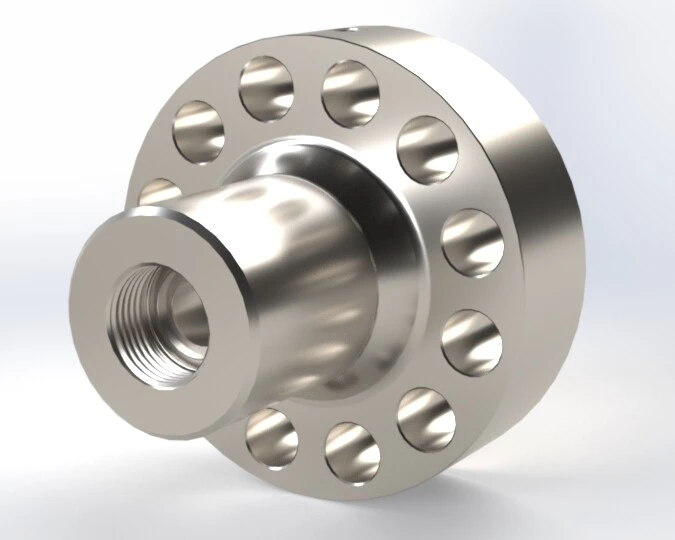

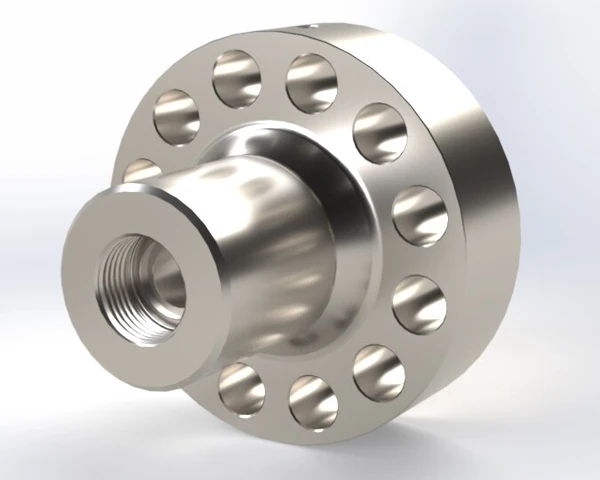

END CAPS

End Caps That Match Your Other Components

The end cap is a necessary part installed on the barrel that keeps plastic contained and helps guide the material into the mold through the die extension.

Base Material Options:

4150, H13, 420V (S90V), Elmax

Treatment Options:

Nitride, Chrome, Ceramic Chrome to name a few

Constructions and Options are based on:

Size, Type and Application

Base Material Options:

4150, H13, 420V (S90V), Elmax

Treatment Options:

Nitride, Chrome, Ceramic Chrome to name a few

Constructions and Options are based on:

Size, Type and Application